University of Glasgow, Advanced Research Centre

AT A GROUNDBREAKING RESEARCH FACILITY, A SINGLE WORKTOP SOLUTION COVERS THE WHOLE SPECTRUM

AS THE FOURTH OLDEST UNIVERSITY IN THE UK, THE UNIVERSITY OF GLASGOW, FOUNDED IN 1451, HAS A LONG TRADITION OF FOSTERING THE TALENTS OF SCIENTISTS AND SCHOLARS ACROSS MANY DISCIPLINES. IT HAS BEEN HOME TO SEVEN NOBEL LAUREATES AS WELL AS WORLD-FAMOUS LUMINARIES, INCLUDING THE PHYSICIST LORD KELVIN AND ADAM SMITH, ONE OF THE FOUNDING FATHERS OF MODERN ECONOMICS. WITH THE ARC, ITS ADVANCED RESEARCH CENTRE, THE UNIVERSITY IS ADDRESSING THE RESEARCH CHALLENGES OF THE 21ST CENTURY BY OPENING UNPRECEDENTED, CROSS-DISCIPLINARY PERSPECTIVES TO WORLD-LEADING SCIENTISTS.

Andrew Tobin, Professor of Molecular Pharmacology and the ARC’s founding Director, brings it to the point: “The ARC, and the principles behind it, have been a long-term goal of the University. As a name, it encompasses our vision to conduct collaborative, out-of-reach research that has real societal impact. It is so much more than a building. We want to take a shared vision and expertise from across all areas of the University community to genuinely transform the way we do research, with the ultimate aim of changing the lives of the people, community and world around us.”

BREAKING DOWN ORGANIZATIONAL STRUCTURES

HOK, a global player in the world of architecture, engineering and design with 26 offices on three continents, has been in charge of the project from inception to completion, including the laboratory design. As a Senior Associate and specialist for science-related assignments at HOK London, Shem Sacewicz has been involved at all stages. With 20 years of experience and a particular interest in designing for highly collaborative and interdisciplinary research, he was well positioned to develop, together with the project team, the laboratory concept at the ARC. He comments: “Fundamentally, the ARC’s purpose is to provide a collaborative space that leaves behind the traditional college structure and its compartimentalised modus operandi. The ARC is not part of any particular college, and beyond the campus, it is meant to foster interactions and engagement with the industry, the public and the regulators”.

He continues: “To fulfil its mission, the ARC had to be uniquely flexible – which is, by the way, one of the reasons why worktops made of Trespa® TopLab® were ideally suited. I’ll get back to this in a minute. At the outset, considering the goals and the context, there was indeed a vision, but no users: in fact, the projected, interdisciplinary teams and groups had yet to come into existence. Accordingly, we had, at that stage, to resort to a speculative approach. As part of the design process, we created and involved surrogate user groups. They were instrumental in defining the level of versatility that had to be achieved”. With subjects ranging from Creative Humanities to cutting-edge scientific research – and an explicit emphasis on interactions across conventional boundaries – there was indeed no tried-and-tested way to go forward. The expectations and requirements of the actual users could only be met by combining extensive simulation with a holistic perspective.

To fulfil its mission, the ARC had to be uniquely flexible, which is one of the reasons why worktops made of Trespa® TopLab® were ideally suited.” Shem Sacewicz, Senior Associate at HOK London

UP TO CHALLENGING DEMANDS

Shem Sacewicz points out: “The facility includes large laboratories – 1,000 m² on each of the four research floors – where research in a wide variety of fields is conducted, be it Technologies touching Life, quantum physics, biology or chemistry, to name just a few. Then, we had to take into account the highly dynamic and diverse research that is at the very core of the ARC concept. Worktops made of Trespa® TopLab® ticked all the boxes: since they are equally well suited to a very wide range of research environments, they strongly contribute to the enhanced level of flexibility we were aiming at”.

Indeed, choosing Trespa® TopLab® PLUS for worktops in all the ARC laboratories meant that the requirements for an extensive variety of applications and technologies could all be met. Worktops made of Trespa® TopLab® PLUS are extremely reliable in several respects: they are durable, they can take a lot of mechanical stress and they perform well under harsh working conditions. These qualities also makes the worktops future-proof – not the least valuable quality in an environment meant, by design, to keep evolving over time. At this point, it is worth mentioning the added benefits of Trespa’s proprietary EBC technology (Electronic Beam Curing). Beyond the above-mentioned properties of Trespa® TopLab® PLUS, the EBC technology makes the surface resistant to many chemicals and cleaning agents. In wet lab situations, such resistance can prove essential.

TRESPA® TOPLAB® – THE MATERIAL OF CHOICE

Shem Sacewicz explains: “In the UK, Trespa has a high brand recognition and an excellent reputation. On the campus of the University of Glasgow, many researchers were already familiar with Trespa® TopLab® products, and the feedback was very positive. In fact, Trespa was explicitly specified by HOK, as we routinely do for almost all our lab projects: there are very few exceptions indeed”. ALS Labs Ltd is a leading manufacturer of laboratory furniture located in Braintree, Essex, about 40 miles north-east of London. The company serves a wide variety of markets – with clients ranging from the Natural History Museum in London to industrial companies as different as BASF, Honda and Arla, one of the world leaders in dairy products. Gary Sprawling, the Managing Director of ALS, confirms: “As the company in charge of manufacturing and installing the lab furniture at the ARC, we fully share HOK’s preference for worktops made of Trespa® TopLab® PLUS. They are quite simply the gold standard, which is why we use them in 90% of our projects. We have 25+ years of experience with Trespa: there is a lot of history behind our confidence in the product. We simply know it will behave exactly as expected”.

“Still, the ARC certainly stands out, and we developed FlexModular, an entirely new, fully modular system, to meet the Centre’s and HOK’s specifications”

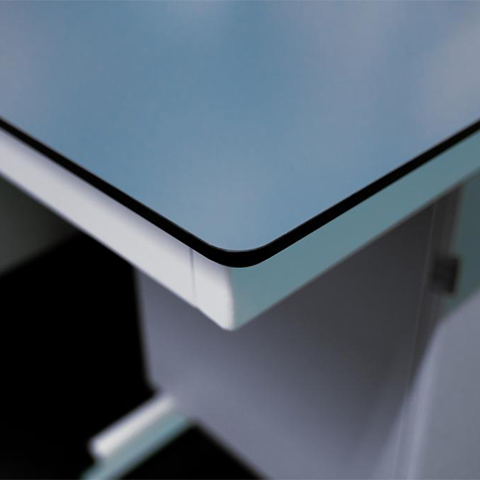

Shem Sacewicz adds: “Full-size mock-ups of all key components, including the worktops made of Trespa® TopLab®, were built as entirely functional prototypes. In this case, we decided to use Trespa® TopLab® PLUS in white with black edges for all lab worktops – a departure from other projects, where we would combine various finishes and colours. The priority at the ARC was different: we wanted to underscore the versatility of the concept, and appeal to all users by keeping a consistent colour scheme throughout”.

A TURNING POINT IN MODULAR LAB FURNITURE

The furniture is designed around mobile, freestanding workbenches. They are complemented by either floor-mounted elements equipped with adjustable shelving or by suspended gantries. Gary Sprawling underscores: “We used Trespa® TopLab® in 20mm for the worktops and 16mm for the shelving. In addition, Trespa® TopLab® was used to manufacture specific, ventilated storage cabinets and waterproof plinths. FlexModular, by the way, has become part of our range of bespoke lab solutions. All components are designed on our CAD/CAM software and cut to size on our HOMAG CNC system. This configuration combines outstanding flexibility with utmost precision. A detail worth mentioning: the modular concept behind this new range is ideal in a BIM environment. In such a case, it optimises, right from the start, the integration and coordination with the wider project design – as was the case with the ARC”.

As the company in charge of manufacturing and installing the lab furniture at the ARC, we fully share HOK’s preference for worktops made of Trespa® TopLab® PLUS. They are quite simply the gold standard.” Gary Sprawling, Managing Director of ALS

“There is, by the way, no lack of opportunities for sophisticated modular systems with multi-purpose, durable worktops made of Trespa® TopLab® PLUS – well beyond the ARC. Defense contractors, healthcare providers, large supermarkets, industrial facilities: it might indeed surprise you how many companies and organisations need top-end laboratory furniture!”.

Shem Sacewicz concludes: “The ARC demonstrates how careful planning and excellent execution can deliver results that met high expectations and a broad spectrum of requirements. Our speculative approach, with surrogate users mimicking interdisciplinary research teams, payed off handsomely. It gave me the information and insights I needed to design unusually versatile labs. The mock-up stage supplied us with extensive reviews by future users. And finally, ALS turned the concept into a modular, highly functional furniture range. It has been in use for about a year now, and judging by the user feedback, it is fit for purpose across the board”.

IT/CH

IT/CH