Zwembad de Boetzelaar

Creëer uw eigen Boetzelaer en bestel hier de gratis puzzel met metallic monsters.

Creëer uw eigen Boetzelaer en bestel hier de gratis puzzel met metallic monsters.

At the start of June 2021, a brand-new swimming paradise will open in Monster, the Netherlands, on the location where swimming pool De Boetzelaer (Monster, the Netherlands) burned down completely at the end of February 2019. The energy-efficient building is characterised by a particularly attractive design and distinctive Trespa® Meteon® wall cladding.

Customised delivery by Jongeneel of Trespa® Meteon® Wall Cladding

Normally, it takes much longer to realise such a project. Because the local authorities were quick to issue the building permit and the parties involved have worked closely together in a special construction team from the start, the swimming pool will soon be ready for use again. We discuss this special project with project leader Michael Jongerius of BAS1S Architecten, planner Ronald Roubos of construction company De Vries en Verburg, account manager Marco Beelen of Trespa, director/owner Martien Lomans of Flow Gevelbekleding and account manager Arno Bos of Jongeneel Eindhoven. Michael explains that children are the main target group of De Boetzelaer: ‘It was a Caribbean pirate-style pool with parrot Paco and his friends as mascots. We wanted to revive that atmosphere. On the outside, this style is symbolised by the shape of a pirate rock. Overall, the building is slightly more spacious than before. There will be a slide from which the children can splash in the recreational pool, a multifunctional room where swimming certificates can be awarded and children’s parties can be held. There will also be a roof terrace.’

Steel structure

Over time, construction company De Vries en Verburg has grown from a stable builder to a modern all-round construction company where sustainability and circularity are of paramount importance. For example, they have a partner agreement with FSC for fully sustainable wood procurement, their environmental management system is ISO-certified and their business operations are certified at level 3 of the CSR Performance Ladder. Ronald Roubos: ‘We have the necessary experience in building swimming pools and, as the main contractor, we were involved in the realisation of this project as early as the design process. This allowed us to switch quickly and that saved a lot of time. It will be an energy-efficient building with more than two hundred solar panels on the roof. The building has a steel structure and the outer walls are made of aerated concrete. The insulation package and the wall cladding have been installed on top of that. This work was carried out by Flow Gevelbekleding. Because of their specialist knowledge and experience, they have been involved in the realisation at an early stage.’

Public Swimming Pool de Boetzelaer

二手产品

Finishes

.jpg)

Finishes

Mounting system

Martien Lomans: ‘In construction, everything revolves around the flow. If all parts of the building process connect smoothly and effectively, it works best for everyone. An effective construction process also saves costs. For this project, we applied the Phoenix substructure system. The advantage of this system is that thermal bridges are limited, which means the heat loss is considerably lower. This system also makes it possible to make the façade structure slimmer. We first attached aluminium corners to the aerated concrete and applied the insulation package. We then mounted aluminium grids in the horizontal direction and screwed a framework of preserved wood on them in a vertical direction. To protect the screw holes against moisture, we first applied black EPDM joint tape before we screwed the Trespa® Meteon® façade panels onto this substructure. The architect’s design provided an equilateral triangle pattern. We mounted them with special screws, in the same colour as the panel material.’

Visual effect

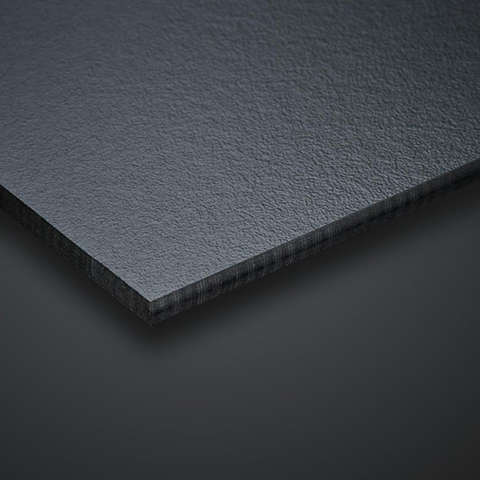

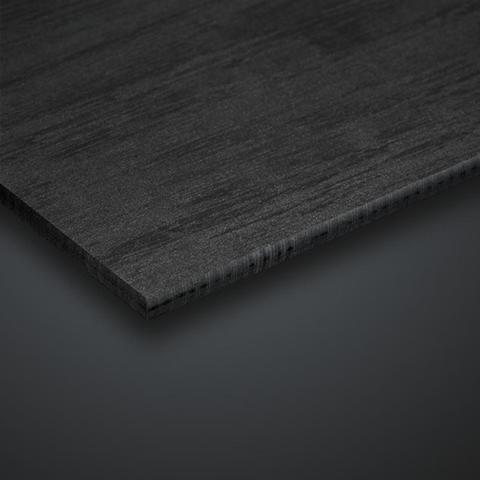

The architect has chosen two different colours and designs from the Trespa Meteon series. Marco Beelen: ‘The panel that determines the appearance of the façade is Aluminium Grey with a satin surface finish. A contrasting colour has been used at the entrance and the entrance to the slide: Natural Slate with a matte surface finish. The visual effect of the façade is determined by placing the triangular panels against each other. The design of these panels has a certain walking direction, so the façade no longer appears flat.’ Delivering this special wall cladding was a logistical challenge. Arno Bos: ‘Jongeneel supplied all the necessary materials, including the insulation material, the aluminium substructure and the wooden framework. In total, it concerned 1,500 m2. The triangular panels were sawn to size and pre-drilled by the Platerij in Utrecht. The input for the CNC machines was provided by Flow Gevelbekleding. They also took care of the entire engineering process.’

.jpg)

ZH/CN

ZH/CN