Top-of-the-range lab solution for a major new production site

Next to the company’s headquarters in Aalen, 70km east of Stuttgart in Southern Germany, Papierfabrik Palm – one of the leading European manufacturers of papers for the printing industry, corrugated base papers and corrugated packaging – has built a brand-new paper mill. Its scale alone sets it in a category of its own: Palm invested half a billion Euros into the project, and to supply the production process with the required amount of steam, the site relies of the two largest water boilers in the world.

This new paper mill, though, is just one of many milestones. Founded in 1872, Papierfabrik Palm operates in the meantime 33 production sites. In 2020, the company generated 1.5 billion Euros in global revenues. In terms of size and success, Palm epitomises the ‘hidden champions’ of the German economy – family-owned businesses that have combined highly professional management with ambitious international growth strategies to expand far beyond the usual boundaries of the category. In addition – and today more than ever – Papierfabrik Palm is ideally positioned to reap the benefits of sustainability: since its inception, the company has been using exclusively recycled raw materials.

In operation around the clock: the new laboratory

A dedicated, spacious laboratory is part of the new mill. Volker Schuberth, the Director of Technology at Papierfabrik Palm, explains: “On the previous production site, we had to deal with three separate labs. This time, we were keen to maximise the available synergies. The new lab reflects this approach: we have centralised the technical equipment and rationalised the operation. In addition, information flow has improved markedly”.

He continues: “The lab fulfils a dual purpose. One is to monitor and analyse the pulp – which is made of broken-down post-consumer paper – as well as make sure the produced cardboard consistently meets our quality criteria”.

“The other is related to water supply and wastewater: the quality of the process water is critical, and we must also closely monitor our own treatment plant, which takes care of the wastewater. Since the mill is in operation 24/7, so is the lab. As a result, this is a very demanding environment for the lab equipment and the furniture”.

.jpg)

Specific requirements – and how to meet them

Starting already with the first of the old mill’s three laboratories, Papierfabrik Palm had opted for steel furniture manufactured by Köttermann, a specialist for laboratory furnishing solutions located in Hänigsen, near Hannover in Northern Germany. The company, which was founded in 1946, has celebrated its 75th anniversary in 2021. Initially, Köttermann focussed on distilling equipment and furniture for pharmacies. In the meantime, the company has developed an internationally sought-after expertise in bespoke lab furnishings. One of the company’s top priorities is complete control over every aspect of production and product quality. Another is maximum flexibility, in order to meet very specific requirements. Therefore, every single product is custom-made in the Hänigsen factory.

Volker Schuberth points out: “The cabinet bodies were made of coated steel, and although some have been in use for 25 years, they still look fairly good. Based on this positive experience, we decided again to ask Köttermann to plan and manufacture the furniture for the new lab”.

“There was ample room for improvement, though, as far as the worktops were concerned. Some of them were tiled, which made them very sensitive to scratches. In other areas, they were made of a conventional wood-based material. As these worktops were in constant contact with water and wet products, they had begun to swell and deteriorate after 10-15 years of use”.

Köttermann had the perfect solution in store. Hans-Jürgen Laur, the Sales Manager for Southern Germany, brings it to the point: “The answer to this issue was obvious – with its TopLab® product line, Trespa® could provide worktops which would be ideally suited for such an environment. Considering the lab at Palm, the Trespa® worktops ticked all the boxes”.

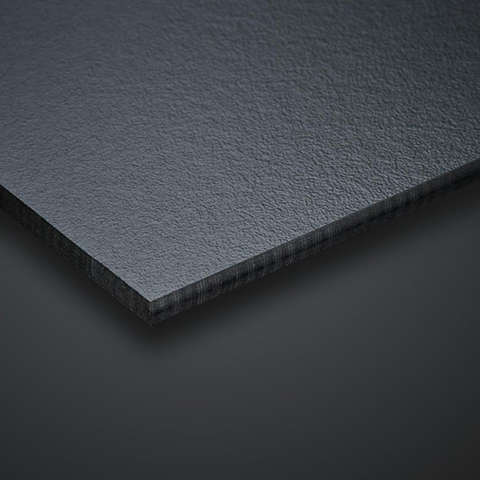

Trespa® worktops are made of HPL (High Pressure Laminate), a material with unique properties. The panels of the Trespa® TopLab® line – which are also available in a version for vertical applications – are manufactured from natural fibres and thermosetting resins. In addition to being homogeneous all the way to their core, they are submitted to an EBC (Electron Beam Curing) process. Developed in-house by Trespa, this hardening process seals the material’s surface and imparts it with exceptional resistance. The panels are available in large sizes, an additional advantage in laboratory environments, where minimising seams and gaps is highly desirable.

“Our new lab includes a wet area that extends over 70m² and a ‘dry’ lab. The latter is used to examine and test the final paper products”, comments Volker Schuberth. “This means that the worktops must not only be water-resistant, but able as well to withstand regular wear and tear, which is just as important in our case”.

For the worktops of the new laboratory at Papierfabrik Palm, Köttermann opted for Trespa® TopLab®PLUS. Beyond its mechanical properties, this variant of the product offers outstanding chemical resistance: it complies with the requirements of the Scientific Equipment & Furniture Association (SEFA) for horizontal surfaces. According to the SEFA 3 test protocol, Trespa® TopLab®PLUS has been exposed to 49 chemicals over 24 hours with no resulting damage. This makes it ideally suited for a wide variety of laboratory environments.

Meeting Palm’s expectations with a bespoke solution

“When we plan a new project, we always focus first and foremost on the client’s functional specifications”, explains Manuela Sterns, who is in charge of external relations at Köttermann. “The laboratory at Palm’s new paper mill was no exception. We started with a thorough analysis of the context. Then, we used our modular furnishing system to design a bespoke solution from scratch”.

Hans-Jürgen Laur adds: “For the lab team, it was essential to be able to stretch out very large paper samples. Accordingly, we designed a worktop with a length of 10m, a section of which widens into a table. The concept includes several useful enhancements, like flush-mount power outlets that are integrated into the tabletop, as well as a wheeled server cart that fits under the table when not in use. This allowed us to maximise flexibility while keeping the worktop itself perfectly flat – as was needed to handle the paper samples”.

He continues: “With its one-of-a-kind finish and its outstanding technical specs, the Trespa® TopLab® worktop outperforms every alternative – be it melamine faced chipboard, polypropylene or ceramic, to name just a few”. Volker Schuberth comments: “By using Trespa® TopLab® worktops, we have been able to meet all our requirements. The material is water and scratch-resistant as well as remarkably strong. It also resists many different chemicals. In addition, I expect it to be particularly durable. In this respect, Trespa’s 10-year conditional warranty sounds definitely convincing”.

Volker Schuberth also likes the haptics and grip of Trespa® TopLab®, even if strength and resistance are what mattered most to him: “I had to make sure that High Pressure Laminate would live up to my expectations, even in the rough environment of a 24/7 lab. To that effect, I submitted a TopLab® sample to a fairly brutal ‘scratch test’. It didn’t affect the material in any way”.

Adding value though visual appeal

When it comes to laboratory furniture, function and technical specifications stand obviously front and centre. But creating an inspiring work environment doesn’t need to be an afterthought. In fact, Trespa® TopLab® lends itself to highly attractive design concepts – right from the start. The product line is available in over 100 sophisticated colours and decors for vertical applications, as well as around 25 different colours and patterns for worktops.

Volker Schuberth is very pleased with the look & feel of the new laboratory: “In the past, we had to put up with reddish-brown tiles which were rather moderately appealing. Our new lab furniture, by contrast, is really classy. The combination of powder-coated metal in ‘Arctic White’ and worktops in ‘Baltic Blue’ is fresh and elegant”.

Manuela Sterns adds: “Both colours are exclusive to Köttermann. The Toplab®PLUS worktops in ‘Baltic Blue’ help create a friendly, welcoming space. This prevents the new Palm lab from coming across as overly ‘frosty’, so to speak”.

Köttermann and Trespa: a shared emphasis on quality

Hans-Jürgen Laur points out: “As a manufacturer of premium solutions, we value consistent quality and dependable relationships”.

“We work closely with Vincent Hamman, our contact person at Trespa – with positive and productive results. We regularly get in touch to coordinate our activities. Worktops are an intrinsic part of any lab. Therefore, they are a crucial component of our furnishing solutions. As a matter of fact, there is hardly a project where Trespa® products are not part of the discussion”.

Hans-Jürgen Laur goes into detail: “Since we only manufacture custom-made solutions, reliable, just-in-time delivery is essential. In the meantime, we have been working with Trespa for several decades. Both companies share a common commitment to premium products. Considering our own positioning, we cannot settle for less: we have to rely on the highest quality when it comes to suppliers and outsourced components”.

He concludes: ”With this project again, everything fell into place. We have been able to plan and build an enduring, high-end lab furnishing solution as part of a very ambitious, large-scale industrial project. It exemplifies a certain type of state-of-the-art test and certification laboratories that are increasingly in demand”.

ZH/CN

ZH/CN